With the maritime supply chain under increasing pressure, shipping companies are simultaneously raking in record profits while facing unusual difficulties.

Even as profits soar, the costs of nearly everything else are rising, including newbuild prices and the costs to recruit and retain crew.

At the same time, attention-grabbing incidents — the Ever Given stranded in the Panama Canal or the costly Felicity Ace fire — have brought more scrutiny to the safety and reliability of global shipping.

All of these issues are interconnected and interrelated, making it both an exciting and a difficult time to be in the maritime industry. The industry seems to be in the midst of a major transition, with market conditions forcing many to adapt and change their operations.

Today’s shipping owners and managers face five key challenges, and only the best will successfully adapt to these changes in the coming years.

1. Meeting Sustainability Regulations

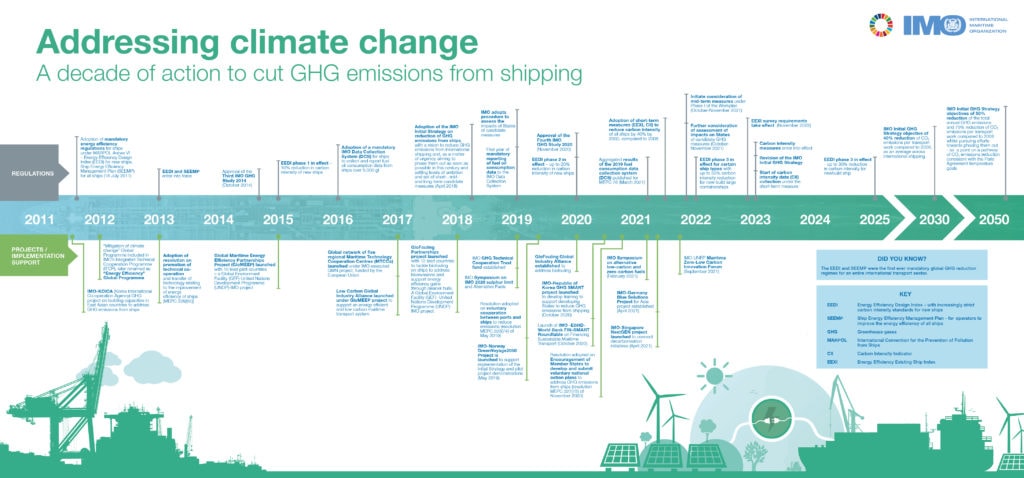

In July 2021, the International Maritime Organization (IMO) announced a new set of regulations designed to cut greenhouse gas emissions from the maritime industry by 40% by 2030. Shipping companies must comply with all new and existing ships by calculating their current carbon footprint, using more energy-efficient fuel, and implementing technology such as cutting sulfur from fuel used onboard ships.

All ships will have to calculate their Energy Efficiency Existing Ship Index (EEXI) and ships over 5,000 gt will establish their annual operational carbon intensity indicator (CII) and CII rating. Any ships rated D or E for three consecutive years must submit an action plan to achieve a higher rating.

Dealing with regulations like this can be a headache, with upgrades to more sustainable materials and fuel being significantly more expensive. While sustainability is a necessary change for the industry, it’s also putting a strain on the bottom line in order to comply.

2. Embracing Digitalization

With a number of new solutions on the market, maritime companies are adopting new technology like artificial intelligence (AI). As the industry evolves toward a more connected, technologically-driven system of fleet management, shipping companies that do not digitize their business — implementing smarter, AI-powered technology on-board ships, modernizing data collection, and investing in crew training for these new technologies — will fail to compete.

It’s one thing to embrace new technology, and a very different thing to effectively implement it. Current onboard systems likely don’t “talk” to one another. Rather than a complete, autonomous solution where you can see all the information you need at-a-glance, most systems require manual data entry from crew members, long printouts, and spotty communication that make it impossible to get a complete picture of daily operations.

Artificial intelligence will sweep away the need for routine and repeated tasks carried out by ship staff, like logging of events, monitoring routine maintenance, and delivering reports. This increased efficiency has the potential to dramatically reshape the entire supply chain, not just on the industry or company level, adding $15 trillion to the global economy by 2030.

Shipping companies need to continue to adapt to new ways of thinking in order to remain competitive and relevant in the industry as more and more companies embrace automation and AI.

3. The Human Element of Safety

One of the shortcomings of a typical “smart ship” application is that it relies heavily on machinery data and sensors, which misses one of the most critical factors on board: the human element.

As much as 96% of at-sea incidents result from human error.

Statistics like these make it seem like every incident is caused by a mistake, but the reality is the systems put in place onboard ships can sometimes contribute to these errors. Human factors — defined by the Oil Companies International Marine Forum (OCIMF) as “physical, psychological, and social characteristics that affect human interaction with equipment, systems, processes, other individuals, and work teams” — refer to the fundamental truth that accidents do happen, and they’re often the result of cultural and operational elements just as much as a technical error.

All shipping companies already have safety protocols and legal compliance in place, but encouraging crew to follow protocols and incorporate safety measures proactively is another thing entirely. Without complete visibility, superintendents and fleet directors cannot effectively assist seafarers in identifying hazards, removing obstacles, or gathering enough information to perform root-cause analyses and create processes that could prevent future occurrences.

4. Adapting Crew to Changing Operations

This rise in new technology naturally gives way to another key challenge: finding and training the right crew members. The maritime industry is no exception when it comes to the “Great Resignation.” Major players now offer huge bonuses and perks to retain their seafarers, from Maersk offering $1000 bonuses and HMM offering a 7.9% raise.

All this comes at a time when the demands on crew members are changing. The shipping industry has a major opportunity as they adopt new technologies to build more autonomous systems. However, this cannot ever replace your crew. The right technology solutions enable them to be more efficient and make better decisions — but they have to know how to use this technology in the first place.

Seafarers will need to adapt and grow their skills in order to keep up with these changes, such as:

- Critical thinking and problem-solving

- Data analysis and visual thinking

- Digital intelligence

- Multitasking

- Retraining on new technologies

5. Big Ships, Small Crew

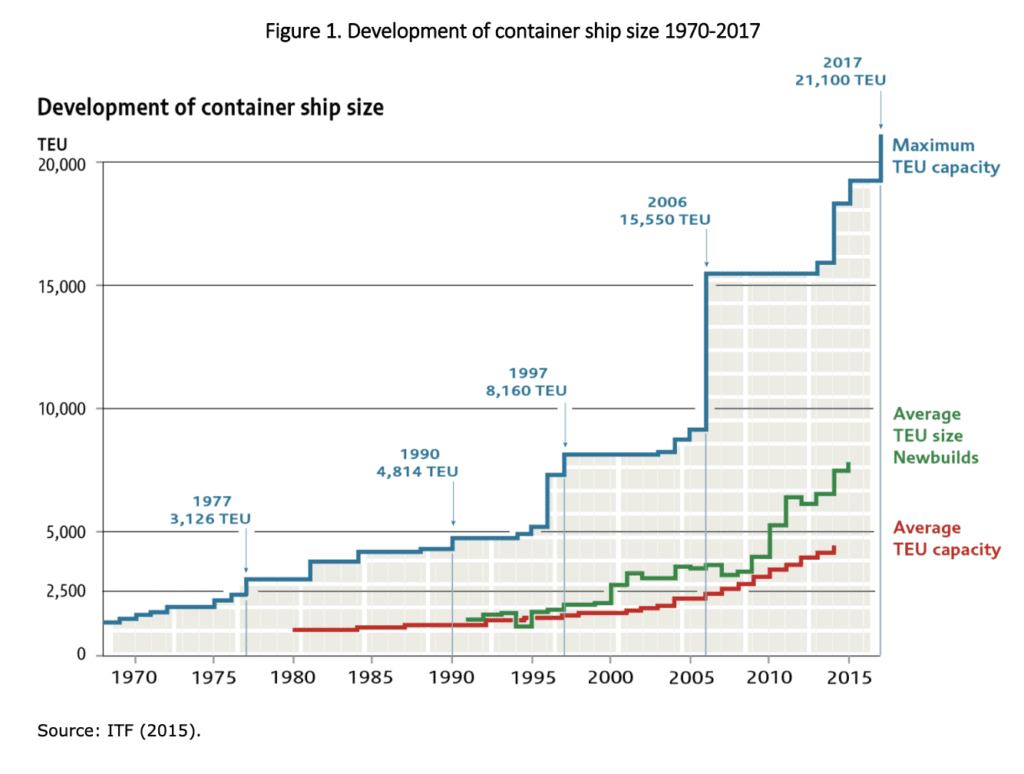

Since the invention of the container 50 years ago, ships now carry 1500% more, with the industry’s largest ships carrying as much as 24,000 standard containers.

With each passing year, ships become larger and larger, like the Ever Ace, considered the largest container ship in the world at 23,992 TEUs. But crew size remains the same or smaller, averaging 15-20 crew members for a ship that can take a half-hour just to walk across. It’s no wonder that we’re seeing more high-profile incidents where even an in-depth investigation can’t tell us exactly what happened. With a wide variety of tasks to accomplish over a vast industrial workspace, it’s impossible to have eyes everywhere at once.

Rise Above These Key Challenges with the Right Technology

Today’s maritime industry is full of some of the toughest, most capable people who are ready to rise to meet these challenges. As shipping companies continue to feel the impacts of the COVID-19 pandemic and a stretched global supply chain, managing operations in an efficient, highly visible manner will become essential to survive and thrive.

It’s critical for fleet owners, managers, and captains to be able to see the complete picture of their onboard operations. This is where the right technology comes in.

With new technologies entering the maritime industry in the hopes of assisting operations, these challenges can be better managed. With the right tools, you can see up-to-the-minute information about ship navigation, maintenance, safety, and security, and much more so owners, managers, and captains can better empower seafarers to do their jobs — building a more efficient and safer maritime industry for all.