A well-reported statistic in the maritime industry is that 96% of at-sea incidents result from human error.

I find that hard to believe, and here’s why: For the vast majority of incidents and accidents that occur at sea, we don’t actually know either what happened or what caused the event in the first place.

Human Error, or Something Else?

For example, the Felicity Ace fire, a high-profile onboard fire led to a loss of $400 million worth of cargo — mainly luxury vehicles such as Porches, Bentleys, and Lamborghinis.

Here’s what we know: The Panama-flagged cargo carrier owned by Japanese company MOL Ship Management (Singapore) had been on a routine run from Germany to the United States off the coast of the Portuguese Azores Islands on February 16, 2022, when fire broke out on board. After launching a distress signal and initiating crewmember evacuation, the ship remained adrift for several weeks until finally sinking on March 1.

Several experts point to the existence of lithium-ion batteries and electric batteries with the cargo as a possible source of the fire. However, even though multiple authorities are currently investigating the incident, it’s still not clear exactly whether the batteries themselves caused the fire, if the cargo was stored incorrectly onboard, or if other safety violations occurred to start the fire.

How can we chalk up an incident like that to “human error”? Or is something else the cause?

3 Factors Driving the Human Error Maritime Statistic

This 96% statistic makes it seem like every incident is caused by a mistake, but the reality is the systems put in place onboard ships can sometimes contribute to these errors. Accidents do happen — but they’re often the result of cultural and operational elements just as much as a technical error.

I believe three main factors contribute to the widespread acceptance of “human error” as the reason behind at-sea incidents: Larger ships, reduced crew sizes, and a lack of risk management culture. I’ll address each one of these in turn.

1. Ships Are Larger Than Ever

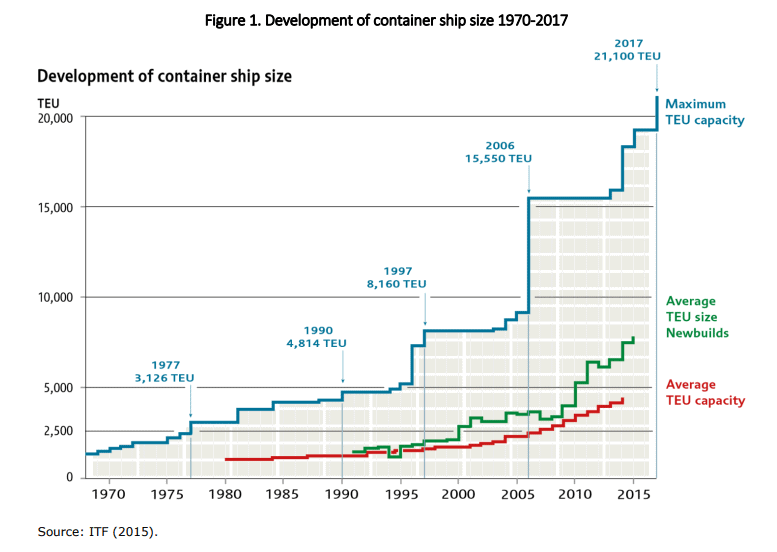

Since the invention of the container 50 years ago, ships now carry 1500% more, with the industry’s largest ships carrying as many as 24,000 standard containers. The average container ship measures 400 meters long by 60 meters wide, with a draft of 60 meters. With each passing year, ships become larger and larger, like the Ever Ace, considered the largest container ship in the world at 23,992 TEUs.

Large ships are here to stay — and they make sense from a business perspective. But as we think about safety and reducing the number of incidents and accidents across a fleet, it’s important to take into account the risks larger ships create:

- The larger the vessel, the more investment and cargo are at risk should an incident occur

- With more cargo comes more chances of hazardous materials interacting with one another or mis-declared as dangerous goods

- Rough seas and big storms can create unsafe conditions, leading to container damage, collapse, or loss

- Larger ships require specific rescue, salvage, and refuge needs that many ports can’t meet

2. Yet Crew Size Remains the Same

While ships grow larger, crew size remains the same or smaller, averaging 15-20 crew members for a ship that can take a half hour just to walk across.

With a wide variety of tasks to accomplish over a vast industrial workspace, it’s impossible to have eyes everywhere at once. Crew members work 24/7 and are expected to handle industrial tasks, maintenance, safety, and navigation in extreme conditions. All this comes at a time when the demands on crew members are changing as ships implement new technologies, handle compliance requirements, and manage larger ships.

That is, if you can even find a crew to hire. The maritime industry is no exception when it comes to the “Great Resignation.” Major players now offer huge bonuses and perks to retain their seafarers, from Maersk offering $1000 bonuses and HMM offering a 7.9% raise. Yet, the job remains challenging for seafarers everywhere.

3. Implementing a Safety-Focused Culture

All shipping companies already have safety protocols and legal compliance in place, but making sure the crew follows protocols and incorporates safety measures proactively is another thing entirely.

Building a culture of safety starts with visibility and accountability, and that starts with the right tools in place to make it easier for crew members to follow safety procedures and handle administrative reporting. Seafarers, fleet directors, and superintendents must identify hazards, remove obstacles, and gather enough information to perform root-cause analyses and create processes that could prevent future occurrences.

To best mitigate risk on board, you need systems that can provide that visibility seamlessly, without any human intervention, and in real-time. That’s where technology can be a powerful asset for your teams. With AI-powered CCTV, you can create better visibility and collaboration between management and seafarers, to make every voyage a safer, smoother one.

Create a Better System of Safety On Board with ShipIn

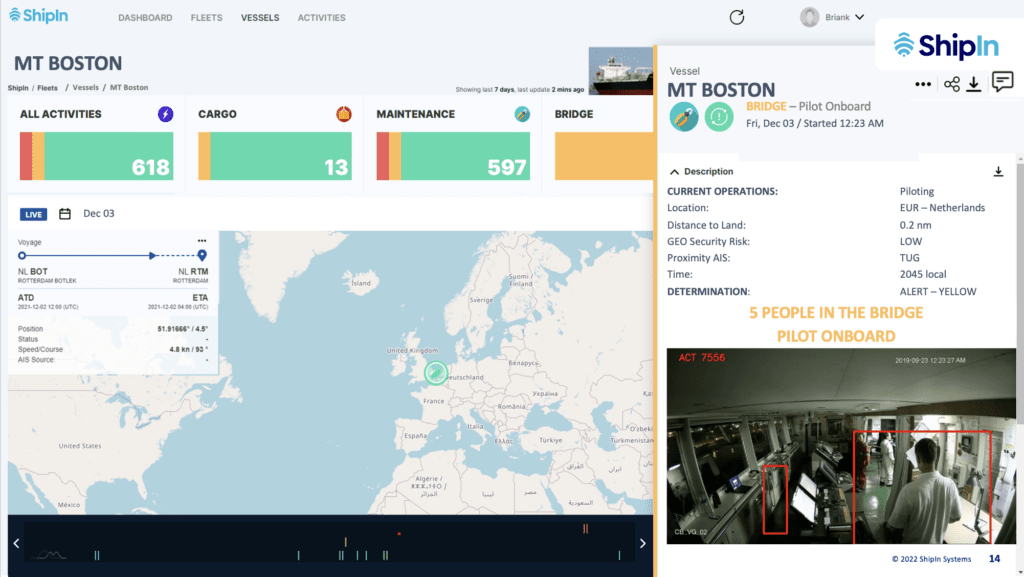

ShipIn sends a network of cameras that crew can install on ships in high-traffic or high-security areas, like the bridge, engineering room, and cargo hold. Rather than watching hundreds of thousands of hours of footage, our proprietary AI technology scans through to identify events and activities of interest, such as real-time hazard and security detection, and patterns, such as time spent in port.

ShipIn’s Visual Fleet Management platform can provide nearly continuous communication and visibility from ship to shore into shipboard activities, shipboard behavior, and shipboard status so that a shore-based manager can review, comprehend, and synthesize such information at-a-glance:

Designed with ship managers and seafarers in mind, ShipIn allows your team to:

- Continuously surface relevant on-board operational incidents for early hazard detection

- Provide visibility to low-traffic areas of the vessel

- Remote guidance and ship-to-shore collaboration

- Automatic logging and reduction of administrative work

- Best practices and assessment for crew competency across fleets

See how ShipIn can help you build a stronger risk management culture today.