Utilising FleetVision™ 3 times per week has been instrumental in improving our operations aboard. Through regular reviews of bridge performance with my team and thorough assessments of mooring operations after each departure, we’ve achieved far greater levels of efficiency and safety. What’s most remarkable is the positive shift I’ve observed in the crew’s engagement and performance since implementing FleetVision™. It is a transformative tool that fosters a culture of continuous improvement and teamwork that has truly elevated our standards.”

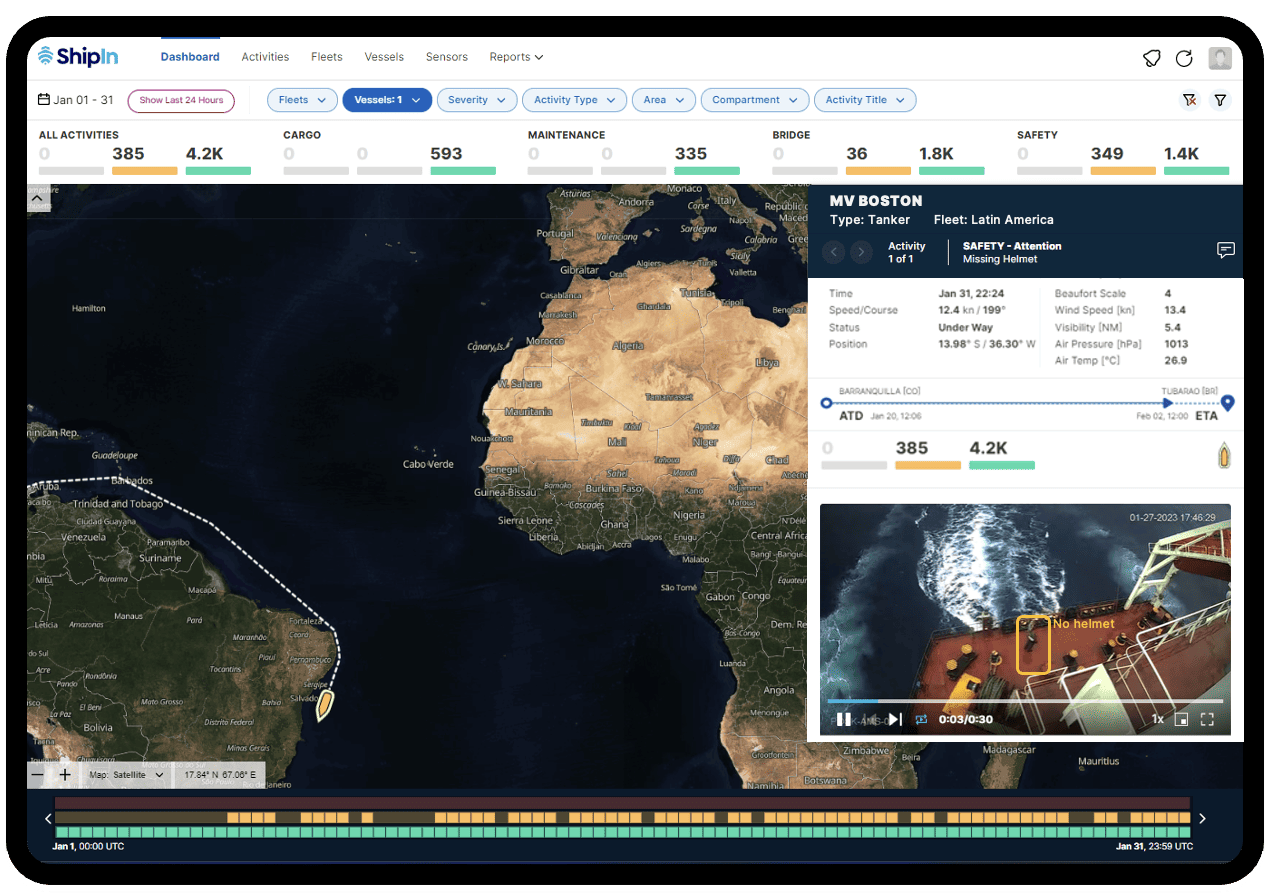

Tufton’s journey with ShipIn’s FleetVision™ has been transformative. With a full fleet deployment, we’ve seamlessly integrated the platform into our operations, enabling real-time insights and enhanced coordination across our entire fleet. Most importantly, the highly positive feedback from our Masters and crew have resulted in significant improvements across all areas of vessel operations.”

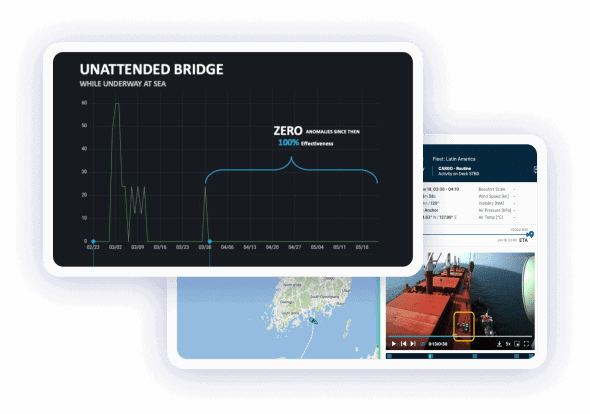

We saw our overall KPIs rise, taper, and then bounce back once we reengaged ships—evidence FleetVision™ helps sustain a proactive safety culture across the fleet.”

FleetVision™ closes the ship-to-shore gap—a bridge between office and ship for better interaction and support”

A leading tanker company was suffering from heavy losses due to recurring, high-profile navigation incidents across the fleet. The company identified a strong need for a proactive system to help improve bridge behavior onboard.

A chemical tanker was fixed on a voyage to load a cargo parcel from a South American port. Upon completion of loading first foot portion, samples drawn from the cargo tank were declared off-spec, and the vessel was held responsible for the cargo contamination. The Quantity of the cargo was 1677 MT with a total value of around USD 800,000.